Glass fibre is used as a PTFE filler as it offers much-improved compression and wears properties. This PTFE Compound material may also be inert gas sintered to further improve creep properties and reduce porosity and gas permeability, whilst also contributing to a loss of tensile properties.

EXPERIENCE & CAPABILITY

Here at Fluorotec, we have helped thousands of clients who have trusted us to machine Glass Filled PTFE into a whole range of components, including Pump housings, valve seats, gaskets, roller coverings, shaft bearings, filter housings and etching plates to name just a small sample. With our expertise and state of the art CNC turning and milling machines, we are often able to deliver solutions that our competitors can't.

The same goes for our PTFE coating capabilities. We are able to make unique improvements or solve any problems you may be having.

Glass Filled PTFE Properties

Glass Filled PTFE is reinforced with glass fibres with the percentage varying between 5% and 40% depending on the needs of the application. As the filler percentage increases so do the properties the filler offers (increased compressive strength, lower deformation under load) but conversely the coefficient of friction properties of the material increases over that of virgin PTFE.

| Property | Test Method | 25% Glass Filled |

|---|---|---|

| Specific Gravity | ASTM D 4894 | 2.23 – 2.26 g/cm3 |

| Tensile Strength | ASTM D 4894 | 31 MPa (4600 PSI) |

| Elongation | ASTM D 4894 | >180% |

| Shore D Hardness | BS EN 13000-2 | 60 |

| Compressive Strength 1% Deformation | >9 MPa | |

| Compressive Modulus | ASTM D695 | 758 MPa |

| Flexural Strength | ASTM D790 | 13.4 MPa |

| Flexural Modulus | ASTM D790 | 1310 MPa |

| Coefficient of Linear Thermal Expansion | ASTM D696 | 7.7-11.2 x10-5°C (100°C) |

| Thermal Conductivity | C177 | 10.6 x 10-4 cal/cm-sec-°C |

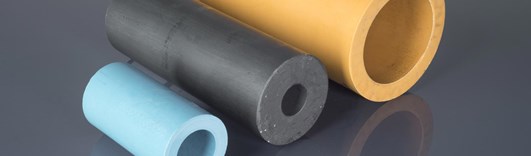

Glass Filled PTFE Parts

Glass Filled PTFE is very commonly used in valve seat applications. Increased compressive strength and creep resistance of the material allow much greater pressure on the valve seat and as such a much higher rated valve. We have also helped customers with Glass Filled PTFE parts for applications such as pump housings, gaskets, roller coverings, shaft bearings, filter housings, transport and conveyor technology and medical & pharmaceutical technology.

Valve SeatsOur Glass Filled PTFE Valve Seats offer decreased compressive strength and lower deformation under load than Virgin PTFE.

Component Design & ManufacturingWe can design and manufacture your product, part or component in Glass Filled PTFE. Whether developing a new part from scratch or innovating to provide a new solution for a failing component, our engineers can design and manufacture products in Glass Filled PTFE that will meet and exceed performance requirements.