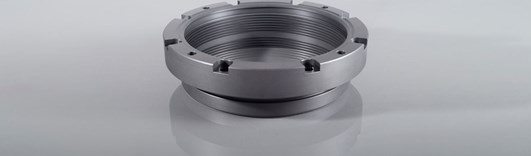

At AFT FLuorotec, we have first-class technicians and machinists that have vast amounts of experience producing Virgin VICTREX PEEK parts and components using our state-of-the-art CNC lathe machinery. We are able to produce exceptional results for materials used for food processing, corrosion-resistant, and high wear applications. Our experts can advise you on the exact material that will be suitable for your needs, and rigorously test it to meet your standards. All materials provided by AFT Fluorotec are fully certified and tested.

In addition to our machining capabilities, we also offer a range of PEEK coatings that can be applied to a number of substrates to create a protective outer layer.

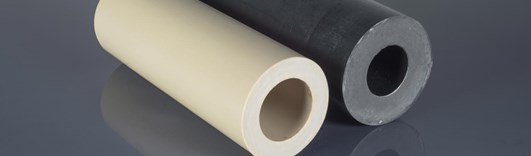

MANUFACTURING IN PEEK