Blog

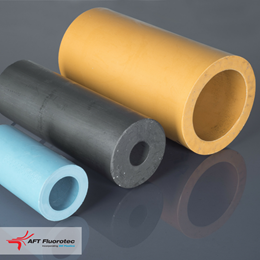

Choosing the best PTFE filler for your application

PTFE can creep and deform under heavy loads, a disadvantage that can be avoided by adding a filler in order to benefit from the properties of both materials. Fillers can also add properties such as improved thermal conductivity, for applications that demand good heat dissipation.

The History of PTFE

For nearly 80 years our everyday lives have been improved by a resin called polytetrafluoroethylene, or PTFE. Discovered completely by accident on 6th April 1938 by DuPont chemist, Dr. Roy Plunkett whilst trying to invent a better coolant gas. After leaving a...

The Properties and Advantages of PTFE

Polytetrafluoroethylene or PTFE (more commonly known as Teflon) is a particularly versatile ivory-white and opaque plastic fluoropolymer; it is made by the free-radical polymerisation of many tetrafluoroethene molecules, and is suitable for a wide range of applications in industries as diverse as aerospace, the food and drink industry, pharmaceuticals and telecoms.

21 Fluoropolymer Facts for Engineeers

Fluoropolymers have an incredible range of commercial uses. Discover our 21 facts for engineers and learn something new.