Our client is one of the world’s largest suppliers of analysing instruments, reagents and consumables, and laboratory equipment to the science and scientific equipment market.

We were already supplying many complex machined components in PTFE and other high performance plastics to this client when we were asked to consider supplying a finished product rather than just component parts.

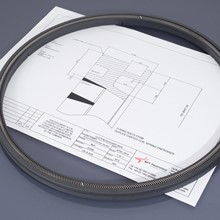

The product, an inerting cap assembly, is made from 12 different component parts that must be manufactured, cleaned, assembled, pressure tested, packaged and boxed. Our client had been buying these assemblies from a USA-based supplier, importing to the UK, modifying for their specific requirements, then re-selling with their own products to their customers.

BRINGING THE PROJECT TOGETHER

We jumped at the chance to provide a complete supply solution, and proceeded to work with the client to develop exact requirements – from material grades and product design to packaging and labelling requirements.

Many of the parts would be manufactured by us, but there were also specialised component parts, which had to be sourced from specific manufacturers. It was our responsibility to ensure that any bought-in parts met our client’s exacting standards.

We worked closely with the client’s engineers on the testing requirements and duplicated the testing equipment and procedure they used to ensure consistency of results.

THE END RESULT

The finished assembly consists of complex machined components in PTFE and stainless steel, specialised laboratory glassware, and many high specification silicone and rubber seals. We stock and supply the complete assembly, tested and packaged ready for immediate despatch by our client to theirs.

This has moved the workload involved with this product away from our client. They now have just one part number covering what was previously 12 part numbers, and no longer require many hours of labour to rework the parts.

By providing a one-stop shop solution to our client for a complex assembly, which involves many differing disciplines of engineering, we are adding value to the supplied product by reducing the workload of our customer.