We are often asked to take over a project when another coating supplier has provided the wrong coating solution, which ends up adding on more cost for the client.

By taking more time at the start of a project to understand the client’s business, specific application detail and what they need a coating solution for, we can recommend an approach that they can be sure will be the best for their business.

What’s the primary purpose of the product?

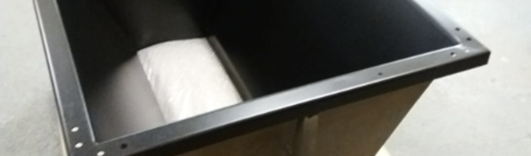

It’s clearly important that a product is fit for purpose – for example, baking trays need to be non-stick and tolerant to high temperatures, or they couldn’t do their job.

That seems pretty obvious, but there are a number of solutions that meet these criteria. This is usually where most coating suppliers will decide which solution to use, but that can lead to problems...

Your equipment has a life cycle, not a singular purpose

Its primary purpose, while important, doesn’t offer the whole picture and can result in the wrong solution being selected.

A baking tray does need to withstand high temperatures, but it also needs to be easily cleaned and stored without damage. These are additional variables which influence the ultimate choice of coating solution and impact:

- The lifespan of the coated equipment

- The quality of finished product

- The cost of maintaining or replacing equipment

By taking the time to understand your equipment and how it is used, we can deliver a superior finished product that really can bring more value to your business.

Choosing the Right Solution

Have a query? Get in touch with our team of experts.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.