Stainless steel thermal spray coatings provide a hard surface, which in conjunction with AFTs PTFE coatings greatly extends the service lifespan of your part compared to a stand alone fluoropolymer coating.

Providing External Reinforcement

Our fluoropolymer (PTFE) coatings are perfect in applications where a non-stick, low friction, dry lubricant or release property is required. With daily wear and use the PTFE layer of your coating will eventually wear away and re-coating will be required. We can extend the time between re-coats by introducing an external reinforcement using a composite coating that includes stainless steel. Composite coatings are a series of protective layers applied to any material, and by adding a layer of stainless steel to your coating we can provide the additional layer of reinforcement you need to increase the lifespan of your PTFE coating.

How does it work?

How does it work?

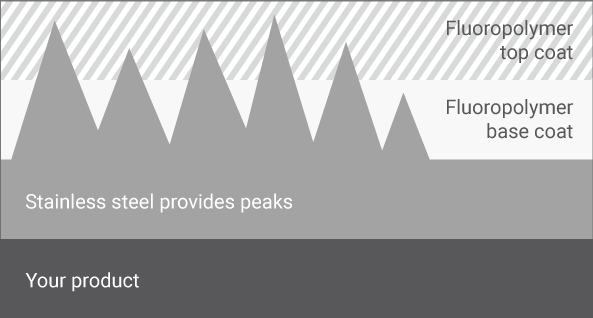

Thermally sprayed stainless steel, produces a ‘rough’ surface finish with a high Ra value (measurement of a surfaces peaks and troughs). The peaks of the stainless steel provide protection for the softer PTFE coating in the troughs, ensuring the properties of the coating are maintained for longer as the comparatively soft fluoropolymer coating is not worn away. This achieves an exceptional wear-resistant composite coating that out-performs a PTFE coating alone, vastly increasing time required between recoats.

It is perfect for use in applications where non-stick, low friction or release is required but the material being moved is abrasive and likely to wear away the fluoropolymer coating.

The ARC SPRAYING PROCESS

Stainless steel thermal spray coatings are often applied by arc spraying. It involves melting a pair of metallic wires (stainless steel in this case) by an electric arc. Once melted down, it is atomised by compressed air and sprayed onto the component. The spray then solidifies on the component surface to form dense and durable coating.

STAINLESS STEEL THERMAL SPRAYING

Contact our team of experts to discuss our coating services.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.