Our controlled pyrolysis burn-off oven is an extremely effective solution for the safe removal of paint, plastic and powder coatings from process machinery and a wide range of components. It works by burning off the unwanted paint/powder coating whilst leaving the original material with little to no damage, offering a prolonged lifetime and multiple usages.

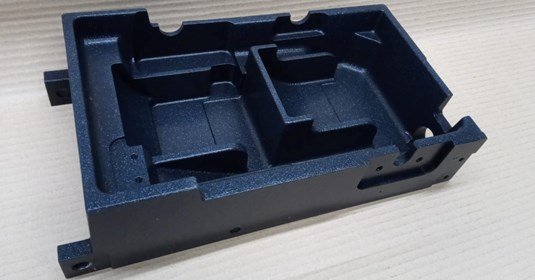

Most powder coating companies use multiple jigs, hooks, fixtures, hanging trees and hangers to hold the parts for the application process of the electrostatic paint/powder coating. After a while these jigs, hooks and fixtures need the powder overspray/build-up removed to enable correct electrical earthing of the parts and to stop cross-contamination. Our rapid turnaround service enables powder coaters to get their equipment back in production quickly and efficiently, plus eliminating time-consuming manual operations for the removal of the paint/powder coating.

COMMERCIAL PYROLYSIS OVEN BENEFITS

There are a number of benefits to using a pyrolysis oven to burn off and remove rust, worn coating and excessive layers from your component.

- Fully automatic: Our burn-off oven is fully automated to ensure consistent, high-quality results.

- Environmentally friendly: Avoiding the use of chemicals means there are no concerns regarding the disposal of hazardous waste. Open stripping tanks with their odours and ignitable fumes can be eliminated.

- Consistent distribution: All elements of the component or material are exposed to the same temperature, meaning you get a more consistent removal of the coating.

VARIOUS APPLICATIONS

Our burn off oven can be used for components that are used across a wide range of industries. For those working in the food & drink industry, we regularly treat commercial baking trays and tins to remove coatings at the end of their lifespan and prepare the surface for recoating with our non stick PTFE coating (Teflon).

For the automation industry, car & bike parts can be treated, as well as things such as automotive and railway brake pads. We can also burn off coatings from steel fabrication parts that are used within the construction industry, leaving the surfaces ready to be recoated with whatever coating is best suited - we are often able to deliver bespoke coating solutions for individual projects.

PYROLYSIS OVEN BURN OFF

Get in touch with our team of experts to discuss your project.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.