PCTFE is a unique fluoropolymer that is capable of maintaining its physical properties at exceptionally low operating temperatures. It absorbs virtually no moisture, meaning it offers great dimensional stability, and maintains its electrical properties in a high humidity environment.

EXPERIENCE & CAPABILITIES

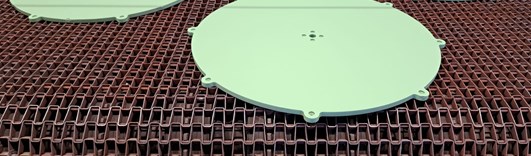

AFT Fluorotec is able to manufacture PCTFE tubes over 700 mm in diameter to be used in the production of valve seats. Our ability to produce a hot moulded PCTFE tube at this size is something that has set us apart from our competitors.

Expansion of our in house moulding capabilities allow us to offer improved lead times and pricing to our customers for these types of products. Our tube moulding capabilities in PEEK and PTFE have already reached 1000mm mm in diameter, and we will continue to expand our range of moulded tubes in melt fluoropolymers such as PCTFE as demanded by customers.

PCTFE Properties

PCTFE can be supplied in thin transparent sheets, with a very low crystalline structure, which offers exceptional optical properties, with the material looking similar to glass. PCTFE in this form is extensively used as sight glasses.

| Property | Test Method | Value |

|---|---|---|

| Density | ASTM D792 | 2.10 – 2.18 |

| Tensile (At break) 23°C | ASTM D638 | 40 MPa |

| Tensile (At break) 100°C | ASTM D638 | 10 MPa |

| Tensile (At break) 150°C | ASTM D638 | 4 MPa |

| Tensile (At break) -129°C | ASTM D638 | 150 MPa |

| Tensile (At break) -252°C | ASTM D638 | 200 MPa |

| Elongation (At break) 23°C | ASTM D638 | 150% |

| Elongation (At break) 100°C | ASTM D638 | 500 - 800% |

| Elongation (At break) 150°C | ASTM D638 | 400 - 600% |

| Elongation (At break) -129°C | ASTM D638 | 9% |

| Elongation (At break) -252°C | ASTM D638 | 5% |

| Hardness 23°C | Shore D | 80 |

| Hardness 50°C | Shore D | 80 |

| Hardness 100°C | Shore D | 67 |

| Flammability | UL94 | V-0 |

PCTFE PARTS

PCTFE has a low melt viscosity which permits extrusion, compression moulding and injection moulding. Typical uses include valve seats, seals, sight glasses and windows and many cryogenic applications.

Valve SeatsPCTFE's stability at low temperature makes it an ideal choice as a ball valve seat or butterfly valve seat material.

SealsPCTFE is a great material for specific sealing applications and our team of experts can help you choose the best performing seal solution for your operating conditions.

Component Design & ManufacturingWe can design and manufacture your product, part or component in PCTFE. Whether developing a new part from scratch or innovating to provide a new solution for a failing component, our engineers can design and manufacture products in PCTFE that will meet and exceed performance requirements.