Filled VICTREX PEEK with 30% Carbon Fibre filler gives the material a very high thermal bearing strength and lower coefficient of friction. This grade provides a much higher thermal conductivity than unfilled VICTREX PEEK.

EXPERIENCE & CAPABILITY

We have been designing and manufacturing precision plastic parts for clients across the world for over 25 years. And as a VICTREX PEEK Approved Processor, our tooling is designed and procedures are controlled to ensure all materials processed have optimum physical properties for the particular VICTREX PEEK grade. We have been trusted to produce Carbon Fibre Filled VICTREX PEEK parts for a number of customers across the oil and gas industry, the energy industry and for customers specialising in mechanical engineering.

Carbon Fibre Filled VICTREX PEEK Properties

Our AF804 Carbon Fibre Filled VICTREX PEEK with 30% fill offers a very high thermal bearing strength and lower coefficient of friction, whilst also giving a much higher thermal conductivity than unfilled VICTREX PEEK.

| Property | Test Method | Typical Values |

|---|---|---|

| Elongation | ISO 527 | 33% |

| Specific Gravity | ASTM D 792 | 1.44 g/cm3 |

| Tensile Strength | ISO 527 | 215 MPa |

| Hardness | Rockwell M | 107M |

| Coefficient of Thermal Expansion | ASTM D696 | 1.5 x10°C |

| Max Continuous use Temperature | 260°C | |

| Colour | Black |

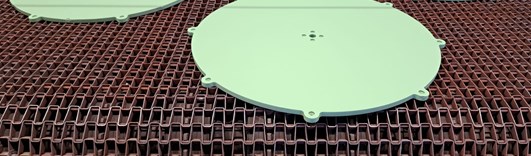

Carbon Fibre Filled VICTREX PEEK Components

Carbon fibre filled VICTREX PEEK is more expensive to produce but is commonly used in applications where a superior strength-to-weight ratio is required. The material is used in numerous applications across multiple industries such as aerospace, civil engineering, sports equipment and a number of consumer and industrial applications. The material's excellent strength has led to it being used in high-performance motor racing as components created with the material have a lower weight than their metal counterparts (and also offer the benefits of less water and electricity used during manufacturing). The construction industry also uses carbon fibre filled VICTREX PEEK to reinforce a range of concrete, masonry, steel, cast iron and timber structures.

SealsIf you need a bespoke VICTREX PEEK seal solution, we'll work with your team to design a seal for your particular application.

Backup RingsOur backup rings can be made to suit any application and in any shape or size.

Component Design & ManufacturingWe can design and manufacture your product, part or component in Carbon Fibre Filled VICTREX PEEK. Whether developing a new part from scratch or innovating to provide a new solution for a failing component, our engineers can design and manufacture products in Carbon Fibre Filled VICTREX PEEK that will meet and exceed performance requirements.