Selecting the right high-quality engineering plastics for specific applications is crucial to achieving optimal performance and durability. Among the top contenders in this category are PEEK (Polyether Ether Ketone) and PTFE (Polytetrafluoroethylene). Each of these materials offers distinct properties, making them suitable for different industrial applications. However, understanding their composition, mechanical performance, and chemical resistance is vital to making the right choice for your use.

What are High Performance Polymers?

High performance polymers like PTFE and PEEK offer exceptional strength, chemical resistance and temperature resistance, making them ideal for demanding applications.

Understanding the differences between PTFE and PEEK is crucial for selecting the right material for your specific industry and use. Both polymers have unique properties that make them suitable for various industries, including aerospace, automotive, and medical.

The choice between PTFE and PEEK depends on factors like chemical resistance, mechanical properties, and thermal stability.

Chemical Structure

PEEK has a molecular structure that includes ether and ketone groups, providing exceptional mechanical properties and chemical resistance. PTFE, on the other hand, is commonly known as Teflon, a synthetic fluoropolymer with remarkable chemical inertness and non-stick properties. PTFE also has a linear thermal expansion, making it highly resistant to chemicals and high temperatures.

The chemical structure of PEEK and PTFE determines their properties and suitability for various applications. Understanding the chemical structure is essential for predicting the behaviour of these polymers in different environments.

Mechanical Properties

When assessing the mechanical robustness of PTFE and PEEK, tensile strength - the maximum stress a material can withstand while being stretched or pulled before necking - is a fundamental measure. PTFE exhibits a lower tensile strength compared to PEEK, implying that PEEK can handle greater stress before failure. PEEK offers superior mechanical strength, making it suitable for load-bearing applications and high mechanical loads. PTFE has a low coefficient of friction, which reduces wear and tear in moving parts.

Creep resistance, or a material's stability under load, is a crucial consideration. Creep refers to a material's tendency to permanently deform when exposed to continuous stress. PEEK demonstrates superior creep resistance compared to PTFE, as it retains its form and strength even under significant, prolonged loads. This is beneficial in sectors such as aerospace, automotive, and medical devices, where materials are constantly under strain.

Thermal Properties

Temperature resistance is a key factor in the performance of polymers in harsh environments. PTFE is known for its excellent resistance to high temperatures, maintaining stability at up to around 250°C while PEEK exhibits greater thermal resistance, withstanding temperatures up to 300°C before showing signs of deformation. This property is essential for applications involving high-heat environments.

Optical and Electrical Properties

Both PEEK and PTFE provide excellent electrical insulation, making them suitable for electrical equipment components. PTFE has a higher dielectric strength and volume resistivity, offering superior voltage resistance. In terms of optics, PTFE allows for more light passage, which can be beneficial in certain industrial applications. While PEEK also has strong electrical insulation, it is slightly less powerful than PTFE, though still adequate for many high-performance situations.

Chemical Resistance and Electrical Insulation

PEEK and PTFE both exhibit exceptional chemical resistance, with PTFE showing pure chemical inertness. PEEK offers good chemical resistance in organic and aqueous environments, making it suitable for medical industries. The chemical resistance properties of PEEK and PTFE make them ideal for harsh environments and aggressive chemicals.

PTFE is a superior electrical insulator compared to PEEK, demonstrating greater voltage resistance which is crucial in manufacturing applications, as it prevents electrical currents from escaping through the electrode body, thereby concentrating all current on the electrode surface for efficient electrochemical reactions.

High Temperature Applications

While PEEK doesn't perform as well as PTFE in low temperatures, it excels in high temperature environments. PEEK can withstand continuous service temperatures up to 250°C and short-term exposure to temperatures as high as 300°C. Its superior mechanical and chemical resistance at high temperatures makes it a suitable choice for more rigorous applications.

Manufacturing Process

Processing Techniques for PTFE and PEEK

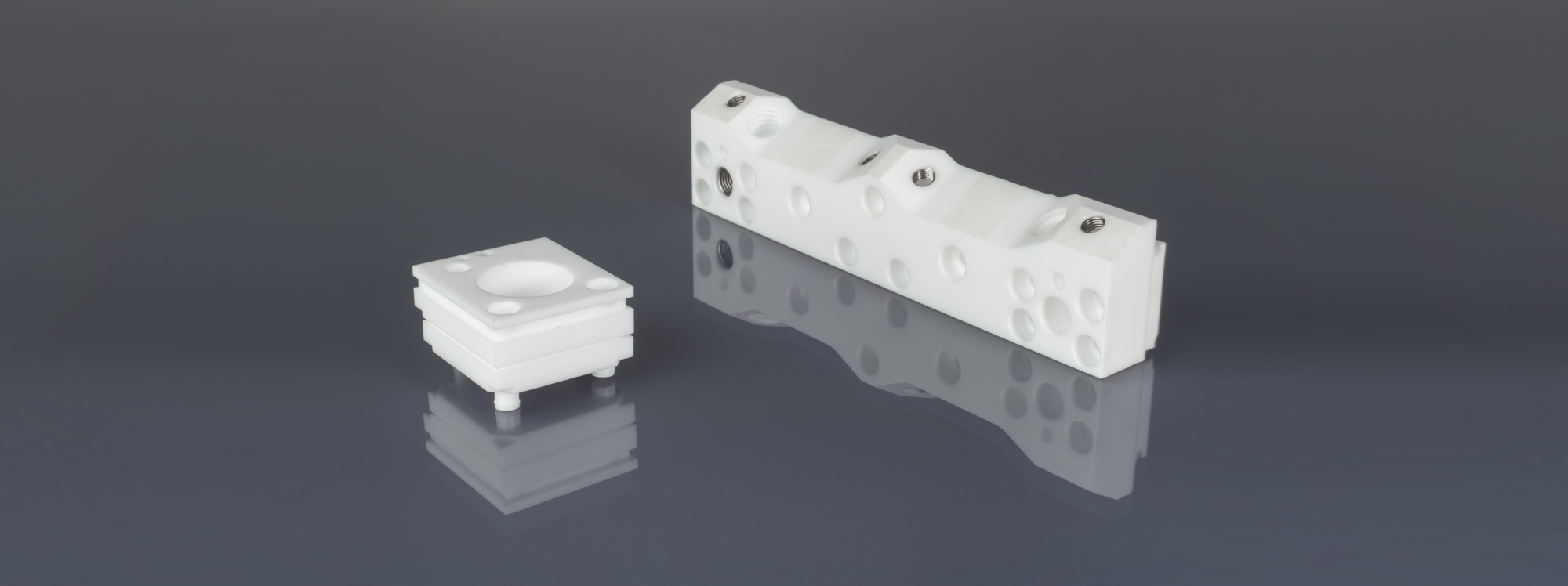

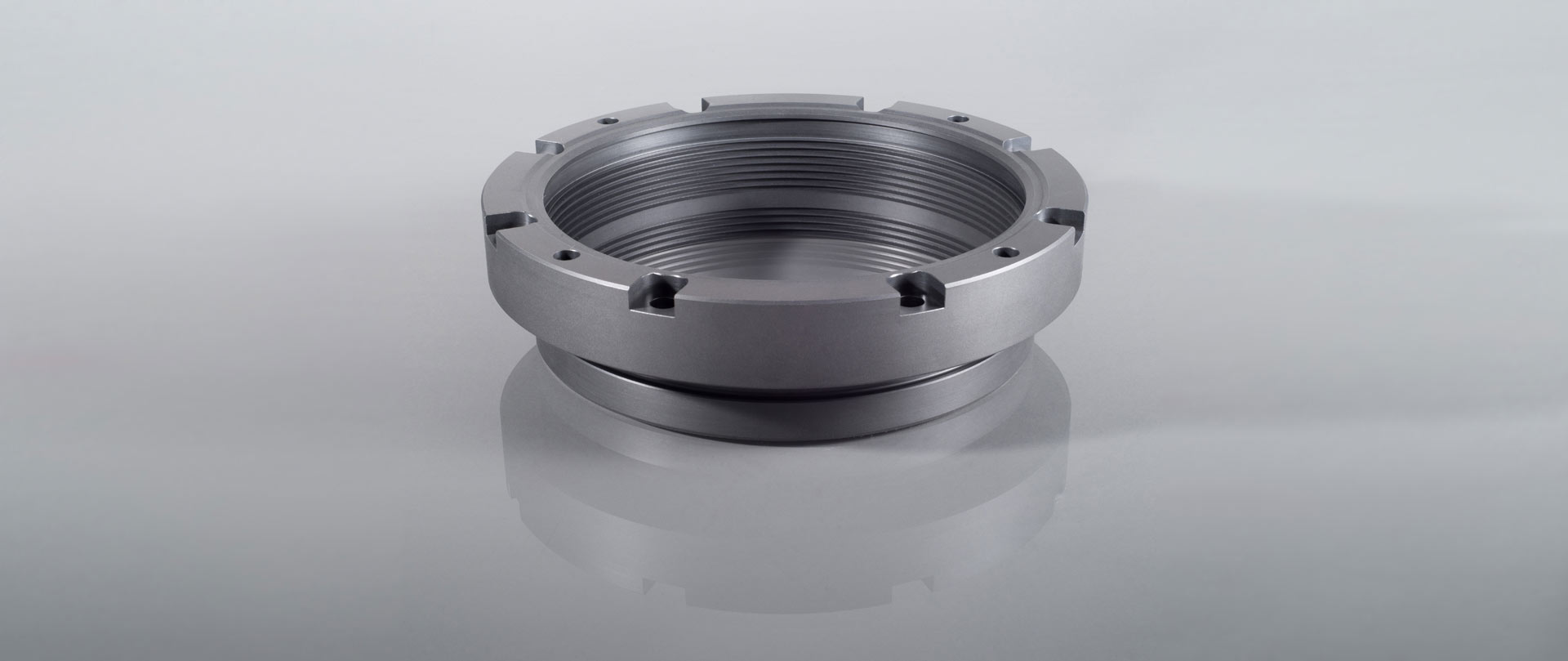

PTFE is typically processed using compression molding and ram extrusion due to its excellent non-stick properties and low coefficient of friction. In contrast, PEEK, known for its robustness, is commonly processed via injection molding and extrusion, and can also be machined into intricate forms.

Industry Applications

PEEK Applications

- Aerospace: PEEK is used in aircraft engines, gears, and bearings where high strength and temperature resistance are crucial.

- Medical Devices: PEEK is biocompatible, allowing its use in implants, surgical instruments, and other medical applications.

- Oil and Gas: PEEK’s resistance to high-pressure, high-temperature environments makes it suitable for downhole tools, seals, and equipment in the oil and gas sector.

PTFE Applications

- Seals and Gaskets: PTFE is widely used in seals and gaskets in the chemical and pharmaceutical industries, where exposure to aggressive chemicals is common.

- Bearings and Low-Friction Components: PTFE’s low coefficient of friction makes it ideal for use in low-load bearings and other sliding applications.

- Electrical Insulation: PTFE is commonly used in electrical insulation applications, particularly where high temperatures or chemical exposure are factors.

We’ll help you choose the ideal material

When considering which material to choose, it’s essential to analyse the application’s temperature, mechanical, and chemical requirements. Our experts can help ensure the right selection for long-term performance and reliability and customise the product to fit your exacting specifications.

Get in touch by contacting 01992 935259.