The addition of Bronze to PTFE gives better dimensional stability and lowers creep, cold flow and wear. Bronze Filled PTFE or Bronze PTFE Compound, increases hardness and compressive strength whilst also increasing thermal and electrical conductivity.

Call: 01992 515880

EXPERIENCE & CAPABILITY

Here at Fluorotec, we have serviced many customers who have trusted us to machine bronze filled PTFE sheets into a whole range of components, including piston rings, compressor parts and high-performance slide plates utilising in-house CNC machinery. Whether it is machined parts, PTFE tubes and rods, or bespoke PTFE coatings, our expert engineers can solve any problems you may be having.

BRONZE FILLED PTFE PROPERTIES

Bronze Filled PTFE is reinforced with bronze powder with the percentage varying between 40% and 60%, resulting in a very hard-wearing material. It has weaker chemical resistance than other grades of PTFE and isn’t suitable for electrical applications.

| Property | Test Method | 40% Bronze Filled | 60% Bronze Filled |

|---|---|---|---|

| Specific Gravity | BS EN ISO 13000-2 | 3.0 – 3.12 g/cm3 | 3.8 – 3.95 g/cm3 |

| Tensile Strength | BS EN ISO 13000-2 | 22 - 27 Mpa | 10 -18 Mpa |

| Elongation | BS EN ISO 13000-2 | 230 – 270% | 100 - 200% |

| Shore D Hardness | BS EN ISO 13000-2 | 65 - 68 | 65 - 75 |

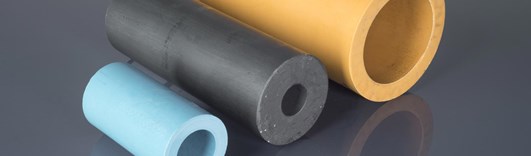

Bronze Filled PTFE Parts

Bronze filled PTFE is an extremely versatile material, used extensively in the compressor industry. We regularly produce Backup Rings and high performance Seals and Wipers. Our dedicated team have the skills and experience to manufacture any bronze filled PTFE parts to your own specification and we can also work with you to design custom components for your project.

SealsAs a specialist seals manufacturer, we've manufactured millions of seals for clients across the world.

Backup RingsWe can manufacture to customer drawings/specifications and design backup rings to suit your specific applications.

Component Design & ManufacturingWe can design and manufacture your product, part or component in Bronze Filled PTFE. Whether developing a new part from scratch or innovating to provide a new solution for a failing component, our engineers can design and manufacture products in Bronze Filled PTFE that will meet and exceed performance requirements.