Our CNC turning and milling facility means we can offer the full engineering service to our customers.

Our inspection and measuring equipment includes a state-of-the-art CNC Coordinate measuring machine, and optical measuring machines.

Call: 01992 515880

Our CNC turning and milling facility means we can offer the full engineering service to our customers.

Our inspection and measuring equipment includes a state-of-the-art CNC Coordinate measuring machine, and optical measuring machines.

Learn more about our CNC milling capabilities and how we can help bring your ideas to life. Our expert team is ready to take on your next project. We offer comprehensive plastic CNC milling services from the micro in size to much larger 1 meter long components.

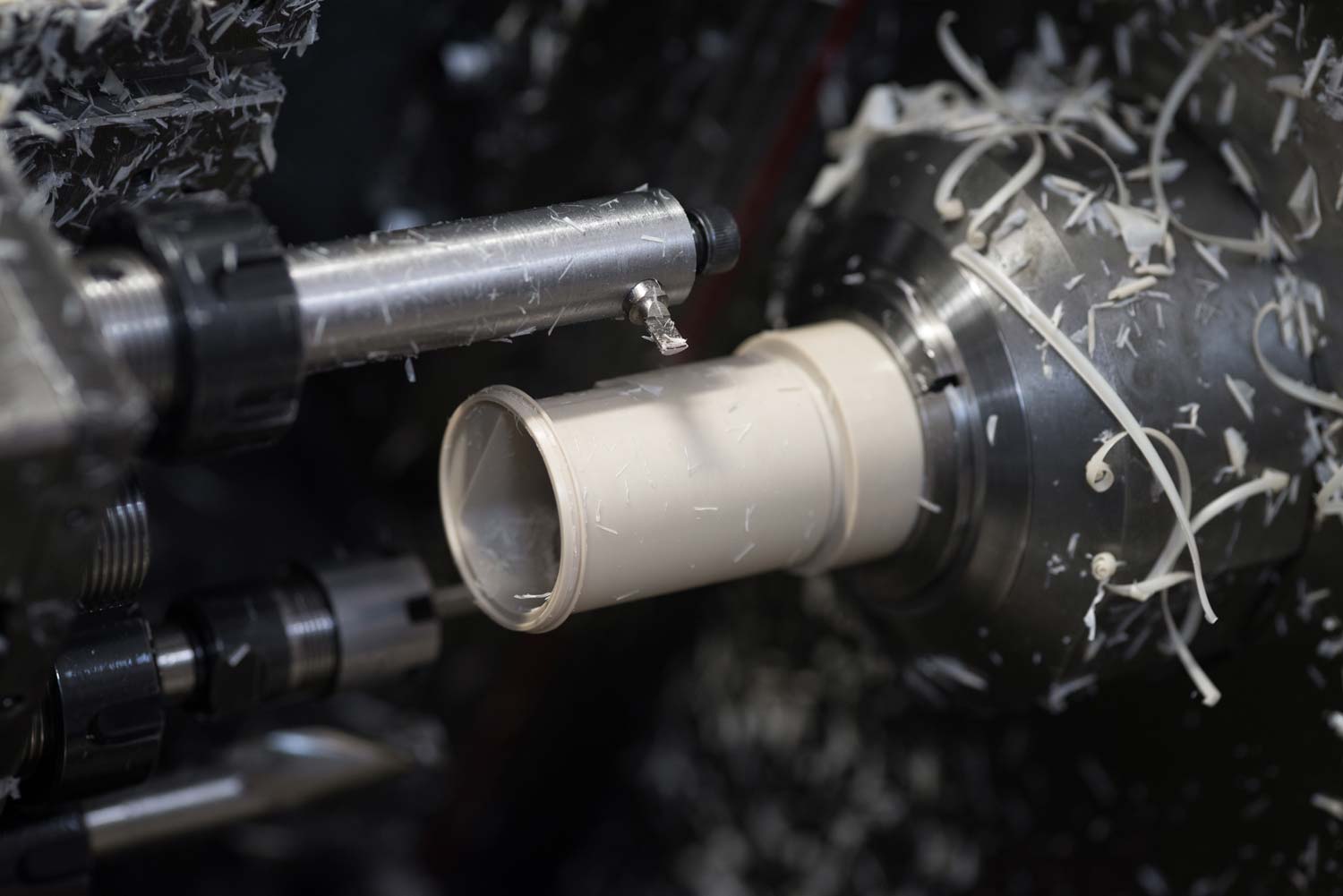

CNC turning of PTFE and engineering plastics. Live tooling on our lathes mean competitive pricing and shorter lead times.

We are proud to have assisted with development of many insulating components with a diameter of 1mm or less.

We provide a bespoke fluoropolymer component design & manufacture service and can deliver the right solution to your problem.

We design and manufacture world-class plastic, rubber and elastomer seals.

When you’ve tried standard profile seals without success or know you’re going to need a bespoke solution for a particular project, we can deliver what you need.

AFT Fluorotec have an extensive range of PTFE materials and we can also produce seals in other materials such as VICTREX® PEEK, PU, FPM and NBR.

AFT Fluorotec have a broad range of experience in designing and manufacturing RCD seals for the oil & gas industry.

From back up rings and mining seals to piston seals and o rings, we offer a wide range of sealing products machined from polytetrafluoroethylene (PTFE).

With outstanding mechanical, thermal and chemical resistance properties, PEEK is an ideal material to use for sealing applications.

We pride ourselves on our expert knowledge of the compressor parts industry, providing a wide range of compounds suitable for your application.

We can produce fluoropolymer tubes and rods in any size, shape or material type.

We can design and manufacture an almost limitless range of VICTREX PEEK back up rings (BUR’s) as well as PTFE rings.

We manufacture valve seats manufactured from our AF range of materials, including PTFE and VICTREX PEEK materials.

AFT Fluorotec have been manufacturing slide bearings for the UK construction industry for many years.

Browse some of our typical PTFE slide bearing and skidway plate configurations and get in touch to discuss your requirements.

PTFE slide bearings can be fixed to the installation by full welding, tack welding, mortar embedment or bolting.

Our CNC turning and milling facility means we can offer the full engineering service to our customers.

Our inspection and measuring equipment includes a state-of-the-art CNC Coordinate measuring machine, and optical measuring machines.

AFT Fluorotec offers comprehensive CNC milling services from the micro in size to much larger 1 meter long components.

We CNC mill all of our core materials including PTFE and PEEK. We realise the importance of providing CNC milling services which our customers know they can rely on, are exact to drawing and are delivered both on time and on budget.

We perform strong quality assurance on all of the parts and components we produce, and our quality of work is guaranteed by our ISO 9001 certification.

Over the years, we have invested heavily in our CNC Turning technology and processes and have the ability to bring clients concepts to life, creating intricate and bespoke components quickly, efficiently and precisely.

From one-off to 1,000,000 pieces, we have no ideal or restricted batch size as everything is machined to order.

From large diameter machine parts (up to 1800mm) to small composite components used in the semiconductor industry, our team regularly advises our clients on the best choice of material and can even work with them to design their components.

The progress made in design software in recent years enables design engineers to re-think engineering limits and set new standards in complexity, performance and miniaturisation. Aft Fluorotec has kept up with those new standards and is an industry leader in producing micro machined plastic parts.

Our highly skilled engineers have vast experience in producing small and even miniature components that are used in electrical connectors, science & medical equipment and devices used in the aerospace and automation field.

With skilled engineers and the latest technology, our plastic machining capabilities are second to none. Whatever your requirements, contact us to see how we can help.

Copyright © 2025

AFT Fluorotec Head Office

Unit F City Park, Swiftfields,

Welwyn Garden City, UK

AL7 1LY

AFT Fluorotec Coatings Manufacturing Site

Unit 4, Swallowfields,

Welwyn Garden City, UK

AL7 1JD

Tel: 01992 515880

Photography by Katie Blair Matthews