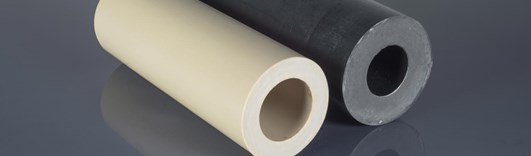

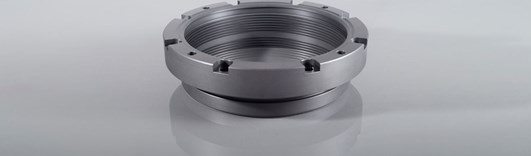

VICTREX PEEK polymer provides exceptional performance over a wide range of temperatures and extreme conditions.

It is a linear, aromatic, semi-crystalline polymer widely regarded as one of the highest performing thermoplastics in the world. It provides a unique combination and range of high-performance properties.