Carbon Capture utilisation and storage (CCUS) will play a key role in global efforts to reduce emissions while ensuring the world can continue to thrive.

Oil and its place in the world has been simplified, with most believing that oil equals Bad no matter what. However, the world still needs plastic. Most plastics are manufactured using the waste derivatives of oil when it's refined into petrol, diesel and other fuels. If we stop using these fuels that oil will still be needed, just with plastic and other material manufacture as its primary purpose. This means finding a way to offset the effects of oil mining to make sure we make and maintain a greener planet. We can help by providing high pressure CO2 solutions to assist carbon capture.

Enhanced Oil Recovery (EOR)

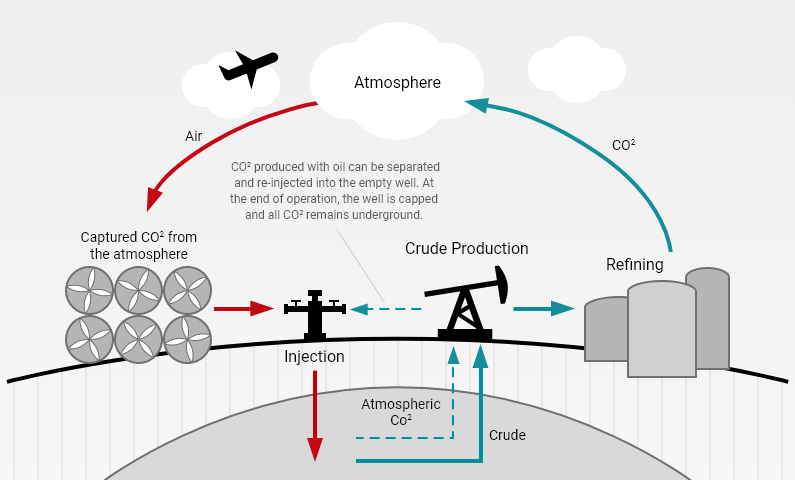

One of the areas where carbon capture is helping offset some negative aspects of oil as an industry is by using waste CO2 to enhance the oil which is recoverable from an oil well. Injecting CO2 into oil reservoirs (Enhanced Oil Recovery) was historically not performed to achieve environmental benefits. But now the CO2 is being recovered and permanently stored in used wells, dramatically reducing the overall carbon footprint of the oil produced. In layman’s terms, CO2 is pumped at pressure into an oil well, which in turn forces the oil out of the well, where it is recovered and captured. This is a process where CO2 can be positively used in an industrial application to recover oil deposits which previously were not recoverable. Once all of this oil has been recovered, there is one final environmental positive as the now empty oil well is filled with waste CO2 where it is permanently stored, stopping it being released to atmosphere or any other greenhouse gas negative action. Laws and regulations support this plan by giving guidance and incentive to operators to ensure the CO2 is stored permanently during the process.

When performed this way, the permanent injection of CO2 into the reservoir can partially or completely counteract the emissions from the oil produced. Or, if the quantity of CO2 permanently stored is greater than what is produced through refining and use of the oil, this activity can produce fuels for transportation while also generating net negative emissions.

There is some reasonable hesitation, given the modern reputation of Oil and Gas as an industry. A more thorough recovery from existing oil wells would slow the advancement to new wells, and it has the permanent environmental positive in safely storing harmful CO2.