When you’re putting together drawings for new construction projects such as supermarkets, car parks and schools, slide bearings should be part of your specification.

There’s a lot more to slide bearings than you may think though. And often, the detail of the configuration required isn’t included in the plans that are used by construction companies on-site.

What slide bearings do

In larger construction projects, PTFE slide bearings are used to carry large loads and movements. This could be in a football stadium, multi-story car park, new bridge construction or a shopping centre.

PTFE is an ideal material for the job because of its low coefficient of friction. PTFE slide bearings successfully address the problems of movement brought about by outside factors, including:

- Changes in temperature

- Strong winds

- Seismic shifts

- Thermal expansion in construction materials

What do slide bearings look like?

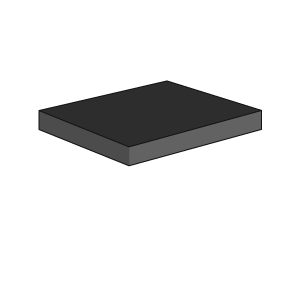

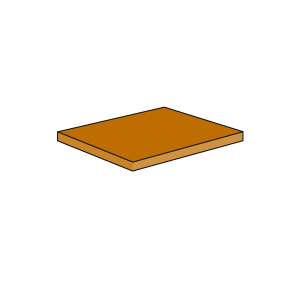

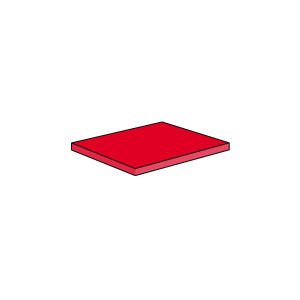

There are two elements to each PTFE slide bearing: the upper and lower element work by sliding against each other.

The upper element is typically the largest of the two - the difference in size being equal to the amount of anticipated movement for any given structure. As a result, the lower element always received a uniform load which provides stability.

There’s no such thing as a ‘typical’ or ‘off the shelf’ slide bearing. This critical point is often overlooked until the bearings are needed urgently on-site. Here’s an example of one below.

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Carbon steel plate / stainless steel plate

- Existing substrate

PTFE SLIDE BEARING

TYPICAL CONFIGURATION

- Top Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Bottom Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Tack welding, full welding, bolting, mortar embedment.

- Load Capacity - Reinforced PTFE: 18 MPa (184 kg/cm2), Virgin PTFE: 7 MPa (71 kg/cm2).

You can see other sample PTFE slide bearing configurations which will give you more of an idea as to how they’re put together.

When are they needed and why?

In an ideal world, getting specifications and quotes for slide bearings would be done by the architect of a project before construction had begun.

However, in reality it’s typically left until the critical stage where someone in a construction firm notices they’re required on-site, but has no idea as to the required configuration, cost or lead-time.

There are a number of reasons why slide bearings shouldn’t be an afterthought, including costly delays to projects.

Whose job is it anyway?

In our considerable experience of designing and manufacturing slide bearings for projects all over the world, the ordering of these vital construction components doesn’t seem to fall on anyone’s shoulders until the very last minute.

We understand that as an architect, you may not consider the configuration, sourcing and pricing of slide bearings to be part of your role. However, there are some compelling reasons why you may want to take a more active role:

- Save your clients time and money

- Go the extra mile for your clients

- Boost your reputation

- Peace of mind that comes with knowing you’ve covered all bases

We often get panicked phone calls from people on-site looking for PTFE slide bearings the next day. Our typical lead time is 7 days so not having these available can cause real headaches all round.

5 things to consider

Here are five main points to think about when it comes to PTFE slide bearings.

- They can be fixed to the installation in a number of different ways: bolting, full welding, tack welding and mortar embedment.

- You need to choose the correct slide bearing configuration to match the installation method.

- PTFE bearings need to be handled carefully and protected to keep the contact surfaces clean and debris-free.

- The overall load of the structure needs to be calculated so we can ascertain the total area required at the relevant temperatures and pressures.

- You don’t need to be a technical expert to source the right slide bearings for your project. Give us a call and we’ll talk through it with you.

Don’t let slide bearings slip through the net on the construction projects you’re involved with. We can ensure they’re properly specced out and part of the plans that are used from the beginning, thereby avoiding unnecessary delays and costs.