Impellers, agitators & stirrers are utilised widely in the industrial mixing industry. Efficient mixing is one of the main factors in maintaining an excellent process within your business.

These parts work in a variety of industries such as;

- Chemical industry

- Phosphates & Fertilizer production

- Minerals Processing

- Food & beverage industry

- Pharmaceuticals

- Environmental – Waste Treatment

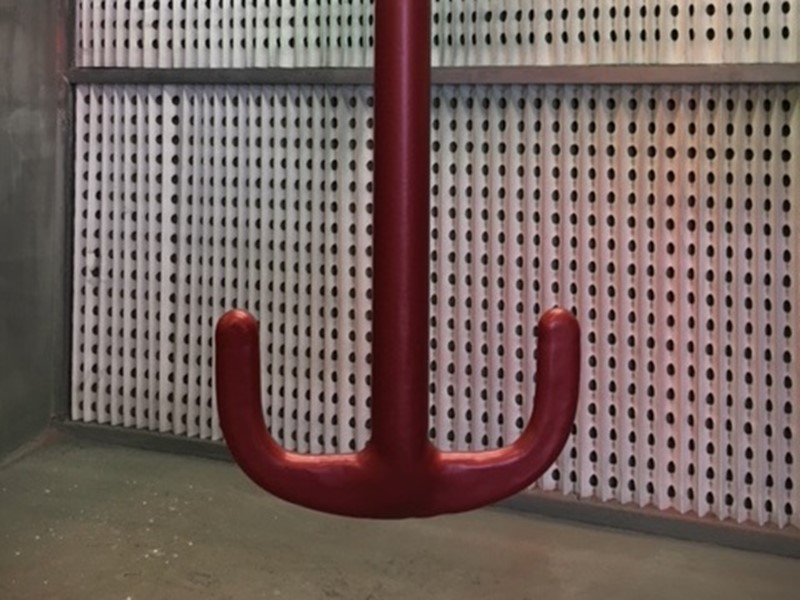

These particular units are for blending and stirring pharmaceutical liquids and gels. These are in an environment full of solvents with varying PH Level. Our AFC 2200 used on these parts is a heavy-duty, high build, chemically resistant coating. This can reach a thickness of 1.2mm.

Due to these parts being used with, corrosive, aggressive chemicals; if the parts are not coated it can lead to a loss of production and an increase in lead times. Coating these parts can help in many ways such as increasing the lifespan of the parts, being cost-effective and improving overall performance. We understand that surface thickness’ can also be an issue with these parts, we can adhere to much different thickness’ to comply with the customers' needs.

We offer various different coatings to suit many industries. For example, if you were to be using a stirrer/impeller in the food & beverage industry, we may suggest a Non-Stick coating as opposed to a Chemically Resistant coating dependent on your process/product.

Get in touch to discuss your bespoke requirements.