One of the many applications that our non-stick release coatings can be used for is the coating of hoppers and chutes that are used across a wide range of industries.

Hoppers and chutes are effective in increasing and maintaining control of product flow during the production process. They can also act as temporary storage and for metering product flow rates.

Hopper coatings are used to prevent products from sticking to the hopper, which can cause build-up and slow down the production process. Customers often approach us when the non-stick coatings on their hoppers and chutes begin to fail, causing product build-up and resulting in poor product quality and increased production times. Thankfully our rapid recoating service means we have been able to recoat the problematic hopper and have it reinstalled with minimal production downtime.

Non-stick Hoppers and chutes for food and bakeware

In the food & drink and industrial bakeware industries, food processing hoppers are used commonly used for things such as bread, cakes, cereals and pasta to name but a few. Without a non-stick coating applied, these items would inevitably stick to the metal. The coatings we have formulated ensure this doesn't happen. These coatings also mean that the equipment is a lot easier to clean after and in between uses. All of the non-stick coatings we use in the food industry are FDA approved and we have a range to choose from depending on your needs.

Non-stick Pharmaceutical hoppers and chutes

In the pharmaceutical industry, hoppers and chutes are often used in the production process of medication and tablets. A constant issue that occurs is that due to the tablets repeatedly hitting off the substrate, they will begin to break up and over time begin to stick to the metal substrate and cause a build-up. Recoating the hopper and chutes with our release coatings ensure the build-up does not occur. Just like the food processing hoppers, the coatings we offer in the pharmaceutical sector are also FDA approved. Chemical protection is also often needed in this industry to provide a barrier between the product and the substrate itself. Our coatings can provide high release properties whilst also giving good chemical protection.

CASE STUDIES

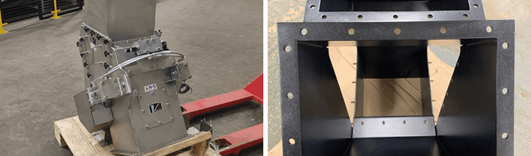

Here are just some of the examples of how we have helped our clients with our hopper and chute coatings: