One of our unique selling points that makes us stand out from our competitors is our ability to provide a rapid service to our clients whilst still maintaining our high-quality standards.

We routinely respond to several maintenance breakdowns for plant and machinery in many different industries. Our ability to provide a fast, flexible service minimises downtime and enables plant engineers to have a planned maintenance window for their production downtime.

Our rapid turnaround (in some cases 24hrs) has enabled businesses to be back up and running with minimal disruption to the customer’s production. Our service includes a complete coating refurbishment with controlled removal of the old coating often resulting in parts being restored to their original manufactured condition.

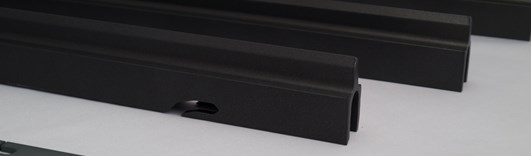

Our coatings are carefully chosen from the full range of Teflon®, Xylan®, Greblon®, Tefzel™ and Halar® finishers plus our own specially formulated AFC range, this enables us to provide the best solutions to many engineering problems. For those applications with extreme wear, a reinforced base coat can be applied which strengthens and prolongs the life of the coatings.

Refurbishment of processing machinery and engineering equipment includes;

- Food processing and bakery equipment (mixers, dough hoppers and chutes, dough rounders and moulds, spreader bars, rollers, cutting/slicing blades, sweet and chocolate moulds and mixing equipment).

- Material handling equipment (hoppers, pumps, tanks, valves, impellers, vessels, tablet chutes, conveyor equipment, guide rails, pulleys, mating parts and rotating equipment).

- Printing and packaging equipment (ink pans, glue tanks, glue rollers, glue nozzles, bookbinding machines, heat seal bars, hot foil tools, scrapers, cutting blades).

- Chemical processing equipment (process vessels, pumps, valves, containers, acid tanks, agitators, pipework, pipe spools, fans, chemical tanks and centrifuges).

Case Studies

Here are just some of the examples of how we have helped our clients with our rapid recoating and refurbishing services: