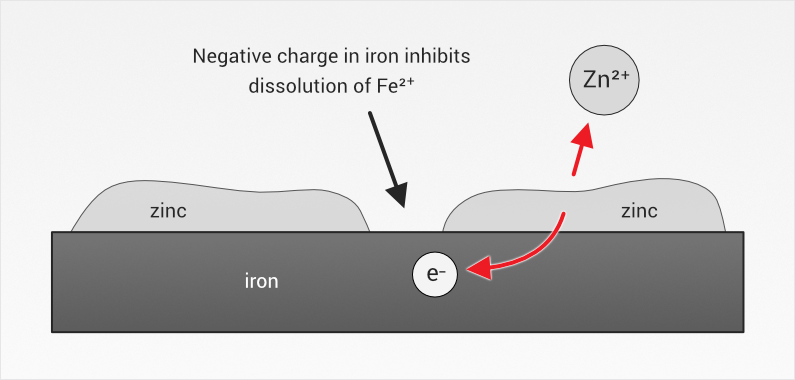

With impressive corrosion resistance properties, zinc is commonly chosen as a protective coating on a number of components that have to withstand harsh environmental conditions and not succumb to rust and corrosion.

The thermally applied zinc surface provides a ‘textured’ finish that is excellent preparation for the application of a topcoat. The topcoat can be applied by either powder coating or utilising AFTs long standing expertise in technically advanced liquid functional coatings.

As the name implies, thermally sprayed zinc is a process where zinc is softened by heating then the small, molten particles are projected onto the cleaned and prepared surface where they adhere to form a continuous protective zinc coating. The combination of thermal then kinetic energy causes the particles to flatten or ’splodge’ onto the surface and other previously sprayed droplets. AFTs thermally sprayed zinc is known as a ‘cold’ process as there is virtually no heat input to the substrate (<80°c so no distortion).

Zinc spraying also allows for a thicker coating to be applied, which extends the component's lifespan making them functional in tougher environments.

Where else are thermally sprayed zinc used and why?

The process is used in numerous applications where sacrificial corrosion resistance is required. AFTs thermally sprayed zinc provides environmental protection for decorative steelwork and sculptures prior to the final application of a powder of liquid topcoat. Architects and designers even request low cost steel items to be thermally sprayed with bronze and/or brass on top the thermally sprayed zinc enabling long-lasting very decorative items to be produced far more cost effectively than with solid bronze items.

As well as giving extended corrosion protection on steel fabrications and castings (up to 50 years), thermally sprayed zinc provides electronic shielding from small handheld devices to communications equipment.

Numerous BENefits

There are a number of benefits to our zince thermal spray coatings when compared to traditional dip galvanising.

- Ideal for large or irregularly shaped components that won't fit into a dipping tank.

- Flexibility - components can be zinc sprayed at the metal fabrication workshop or on site.

- Zero risk of heat warping.

- Thicker coatings means component is able to withstand harsher environments.

- Process is faster and is less expensive than dip galvanisation.

ZINC THERMAL SPRAY COATINGS

Contact our team of experts to discuss our coating services.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.